New EU Rules Revamp Battery Safety, Recycling, and More (EU Regulation 2023/1542)

Leave a CommentThe rise of lithium-ion batteries has changed how we power our world. From electric vehicles (EVs) and e-bikes to household devices and even powering the electrical grid, they are prevalent in more applications than ever. According to the European Commission, the global demand for batteries may increase up to 14-fold by 2030. However, as their popularity surges, so has the push for stronger safety and environmental regulations.

Why Lithium-Ion Battery Safety Needs Attention

The potential safety risks associated with mishandled lithium-ion batteries are causing concern. Incidents during transport or storage within residential or commercial buildings can lead to devastating property losses and significant increases in insurance premiums. Some residential buildings, hospitals, and transit systems are preemptively banning e-bikes and other products powered by these batteries within their facilities. Stakeholders in the battery industry must address these concerns to ensure the continued adoption of lithium-ion technology.

Another issue arising as lithium-ion batteries become more popular is consumer awareness of proper disposal methods. Disposal of lithium-ion batteries in regular waste bins can be dangerous. Crushing during trash collection and handling can cause them to ignite and potentially cause fires. These batteries not only power electric vehicles, e-bikes, e-scooters, and small personal devices like phones and laptops, but also unexpected items like singing greeting cards. Some argue that their use in unexpected products is irresponsible by manufacturers, as consumers may unknowingly dispose of them improperly.

EU New Battery Regulation 2023/1542

To combat these issues the European Union (EU) published the EU New Battery Regulation (EU) 2023/1542 on July 28, 2023, in the Official Journal of the European Union. Just weeks later on August 17, 2023, the Regulation was officially put into effect. It covers all batteries available on the EU market and aims to improve sustainability, safety labeling, and waste management. The Regulation supports the shift to a circular economy and increases the security of supply for raw materials.

Scope of applications and battery sizes

The EU New Battery Regulation includes both rechargeable and non-rechargeable batteries. It is relevant for manufacturers of cells, modules, battery packs, energy storage systems, EV battery systems, and end products utilizing batteries. The regulation itself casts a broad net, encompassing battery categories such as waste portable batteries, electric vehicle batteries, industrial batteries, starting, lightning, and ignition batteries, and batteries for light means of transportation such as e-bikes, mopeds, and e-scooters. While specific rules within the regulation place stricter requirements on larger batteries exceeding 2 kWh, batteries of all sizes are affected.

However, small to medium-sized enterprises with less than 250 employees and an annual turnover of up to 50 million Euros or a balance sheet total of no more than 43 million Euros are exempt from many of these requirements unless they produce batteries over 2 kWh capacity. This includes Excell Batteries as their largest rechargeable battery in 540Wh, and the largest primary stick packs are approximately 2kWh.

Key requirement: replaceable batteries for portable devices

As part of the Regulation, the EU will require all portable devices sold within the bloc to have replaceable batteries by 2027. This applies to all smartphones, laptops, and tablets, including those produced by Apple, Samsung, and Google. This is just one example of how the Regulation will likely significantly impact the rest of the world, despite being an EU directive. It is unlikely that manufacturers will produce two different versions of their products – one for the EU and one for the rest of the world.

Key requirement: battery passport

To ensure compliance with the EU New Battery Regulation, EV and industrial batteries over 2 kWh will be required to have a unique digital battery passport accessible via a QR code integrated into their label. The battery passport will include relevant data from the entire battery lifecycle including battery chemistry, capacity, performance, safety, cycle life, carbon footprint, and calendar data.

Key requirement: label markings

The EU New Battery Regulation also imposes new requirements for CE markings. An abbreviation of “Conformité Européenne,” or European conformity—the CE mark has been around since 1993, and serves as a way for manufacturers to declare that their product complies with all the applicable legal requirements within the European Economic Area.

All portable batteries sold within the EU market will need to carry the CE marking by August 2024. Compliance is self-declared and obligations depend on the type of battery.

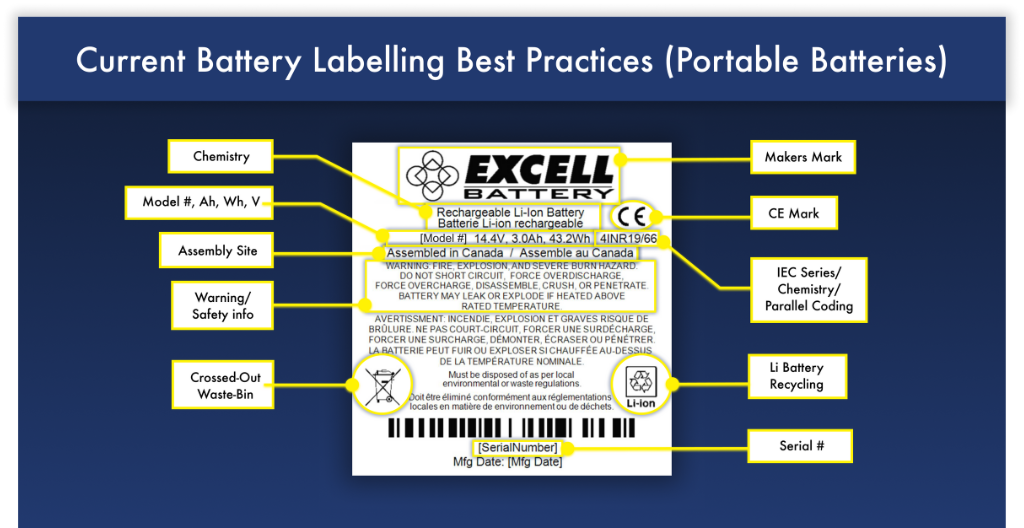

The current best practices for battery label compliance are:

- CE Mark,

- Makers mark,

- Assembly site

- Serial number,

- Model number,

- Warning/safety information,

- Battery chemistry

- Ah,

- Wh (best practice, but also mandatory for Li-Ion batteries),

- Voltage (best practice, but also mandatory for Li-Ion batteries),

- Crossed-out waste bin symbol

- Lithium battery recycling symbol

- IEC series/chemistry/parallel coding

For lithium primary (non-rechargeable) batteries, the amount of lithium in grams is also required.

Those best practices are highlighted on the portable battery example label below:

Figure 1: Current Battery Labeling Best Practices (Portable Batteries)

Key requirement: responsible sourcing

The EU New Battery Regulation echoes existing initiatives like RoHS and REACH by including language that discourages battery manufacturers from using certain materials. Additionally, the regulation mandates responsible sourcing of base materials, prohibiting the use of conflict minerals obtained through practices like slave labor, environmentally damaging mining, or practices that violate health and safety standards.

Timeline

The EU New Battery Regulation encompasses a significant number of mandates that will gradually roll out over the next few years with the goal of reaching climate neutrality by 2050. Stakeholders in the battery industry should be aware of the following timeline for the Regulation. It is of note that most of the upcoming requirements of 2023/1542 only apply to batteries greater than 2 kWh at this point. As we approach the following dates, it is important to check the criteria for any regulatory implementations:

February 18, 2024: Mandatory enforcement of the Battery Regulations

August 18, 2024: Mandatory enforcement of safety requirements for stationary battery energy storage systems, performance and durability requirements for rechargeable industrial batteries with a capacity greater than 2 kWh, LMT batteries and electric vehicle batteries, conformity assessment procedures, and economic operator obligations

February 18, 2025: Mandatory enforcement of carbon footprint requirements for electric vehicle batteries

August 18, 2025: Mandatory enforcement of supply chain due diligence / Mandatory enforcement of waste battery management

February 18, 2026: Mandatory enforcement of carbon footprint requirements for rechargeable industrial batteries

February 18, 2027: Mandatory enforcement of battery passports for rechargeable industrial batteries larger than 2Kwh and electric vehicle batteries / Removability and replaceability of portable batteries and LMT batteries

August 18, 2028: Mandatory enforcement of requirements for recycled materials in rechargeable industrial batteries with a capacity greater than 2 kWh, except those with exclusively external storage, electric vehicle batteries, and SLI batteries, conformity assessment procedures, and economic operator obligations.

What EU New Battery Regulation (EU) 2023/1542 Means for OEMs

OEMs that may be impacted by the EU New Battery Regulation (EU) 2023/1542 should involve their battery suppliers early in the product design process to ensure timely compliance. All companies doing business within the European market must undergo IEC 62133 testing to verify their batteries meet safety requirements. Additionally, they need to meet labeling requirements and best practices, including affixing the CE mark. The complete directive can be found here.

The EU New Battery Regulation isn’t the only set of rules that manufacturers and users need to be aware of. A few examples include the previous EU Battery Directive, which has been in effect since 2006. It focuses on the chemical content of batteries, and recycling practices, and establishes requirements for battery capacity, and rating.

Another important directive is the Electromagnetic Compatibility (EMC) Directive (2014/30/EU). It ensures that electric and electronic equipment, including those powered by batteries, don’t interfere with the functionality of other devices through electromagnetic emissions.

Applicable both inside and outside of the EU, the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO) are introducing new regulations specifically for the transport of lithium-ion batteries. These regulations, effective on January 1, 2025 , limit the state of charge for all lithium-ion batteries transported by air, land, or sea to 30%. It applies regardless of whether the batteries are shipped loose or packed as part of an end product.

Excell Battery Company: Your Partner in Compliance

With over 30 years of experience, Excell Battery Company has established itself as a trusted partner for OEMs navigating the complexities of battery regulations. Through a commitment to continuous learning, Excel maintains a strong understanding of the ever-evolving regulatory landscape. This includes changes in regulations, training requirements, label requirements, and packaging requirements. Excell works closely with their customers to ensure compliance and create a better battery industry for everyone.

The EU’s New Battery Regulation 2023/1542 marks a significant step toward a more sustainable and responsible future for lithium-ion batteries. By addressing safety concerns, promoting responsible sourcing, and ensuring steps toward circularity, the Regulation will ensure the continued growth of lithium-ion technology. While the regulation targets the EU market, its impact will likely be felt globally as manufacturers strive for consistency across their product lines.